VCX -80/315T SERIES SEMI CLOSED PRECISION STEEL FRAME PUNCH

The fuselage is welded with steel plates and has a D-shaped opening structure.

The rectangular six sided guide rail design directly absorbs the lateral force of the fuselage, greatly improving the stability.

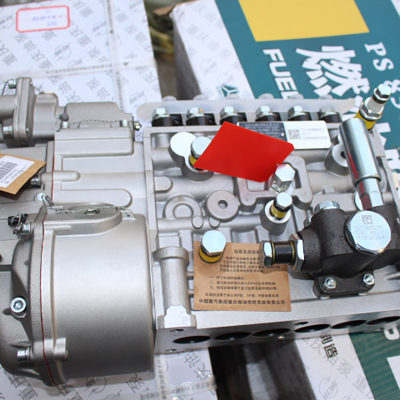

Crankshaft, transmission shaft and other important parts are made of high-quality steel and have undergone heat treatment.

The advanced electrical control system, together with efficient dual solenoid va lve and overload protection device, ensures the safety of the equipment.

The main transmission gear soaks in and closes the oil pool. With the gear grinding process, the noise is reduced and the wear resistance and transmission stability are improved.

With the automatic feeding device, the production cost can be reduced and the production efficiency can be improved.

With the support of humanized interface, the operation is simple and convenient.

VCX -80/315T SERIES SEMI CLOSED PRECISION STEEL FRAME PUNCH

Machine type | VCX-80 | VCX-110 | VCX-160 | VCX-200 | VCX-260 | VCX-315 | |||||||

Model | V | H | V | H | V | H | V | H | V | H | V | H | |

Capacity | Tons | 80 | 110 | 160 | 200 | 260 | 315 | ||||||

Rated tonnage point | mm | 4 | 2 | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 7 | 3.5 |

Stroke Dieheight | mm | 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | 300 | 150 |

mm | 340 380 | 360 | 410 | 460 510 | 460 510 | 500 | 550 | 475 | 550 | ||||

Stroke Per Minute | 35-80 | 80-120 | 30-60 | 60-90 | 20-50 | 40-70 | 20-50 | 50-70 | 20-40 | 40-50 | 10-25 | 20-35 | |

Slide adjustment | mm | 80 | 80 | 100 | 110 | 120 | 120 | ||||||

Slide area | mm | 560×420×70 | 650×470×80 | 700×550×90 | 850×630×90 | 950×700×100 | 1000×750×110 | ||||||

Bolster area | mm | 740×550×90 | 880×600×110 | 960×800×140 | 1120×820×160 | 1280×840×180 | 1380×900×200 | ||||||

Main motor | Kw. p | 7.5×4 | 11×4 | 15×4 | 18.5×4 | 22×4 | 30×4 | ||||||

Slide adjust device | ric driving | ||||||||||||

Air pressure | Kg/cm² | 5-6 | 5-6 | 5-6 | 5-6 | 5-6 | 5-6 | ||||||

Presses dimension | mm | 1300×1890×3000 | 1420×1985×3200 | 1600×2200×3500 | 1750×2500×3900 | 2080×2895×4470 | 2100×2925×4550 | ||||||

Presses precision | GB(JIS) 1class一级 | ||||||||||||

Die cushion capacity | Tons | 3.6 | 6.3 | 10 | 14 | 14 | 14 | ||||||

Die cushion stroke | mm | 70 | 80 | 80 | 100 | 100 | 100 | ||||||

Die cushion effective area | mm² | 450×310 | 500×350 | 650×420 | 710×480 | 810×480 | 810×480 | ||||||